Controller Area Network (CAN) electrical systems began to appear in new vehicles in 2003. Since then, more and more vehicles have been equipped with CAN systems, until 2008 when virtually all passenger cars and light trucks sold in the U.S. were CAN-equipped.

As a vehicle owner or do-it-yourself mechanic, you need to know how CAN has made the electrical system in late model cars and trucks much more complicated than ever before. CAN allows various modules and systems to share data and interact in ways that where previously impossible.

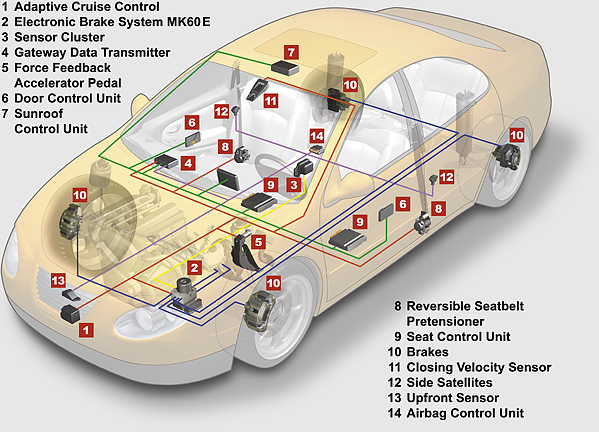

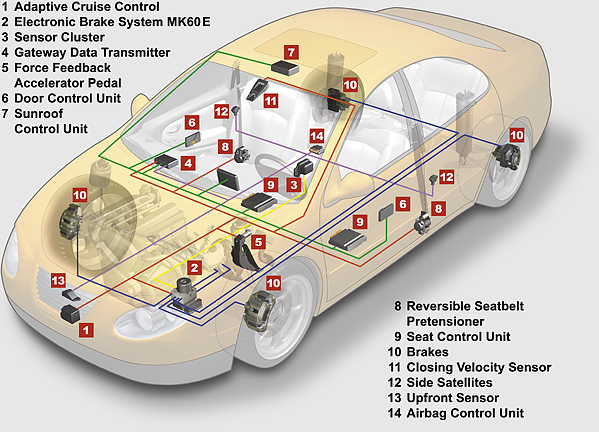

So what exactly is CAN? It is a communication standard that allows the various modules and computers in a vehicle to talk to one another via a common "data bus" circuit in the wiring system. Think of it as a high speed party line that allows data and commands to zip back and forth from one module to another. This allows the Powertrain Control Module (PCM), antilock brake/traction control/stability control system, electronic steering, electronic suspension, automatic climate control system, keyless entry system, lighting control modules and dozens of other systems and modules to all be interconnected electronically.

The Development of Controller Area Networks for CarsCAN was created in 1984 by the Robert Bosch Corp. in anticipation of future advances in onboard electronics. The first production application was in 1992 on several Mercedes-Benz models. Today you will find it on all new vehicles.

CAN Diagnostics

CAN DiagnosticsIf you don't know the difference between a CAN data bus and a school bus, you're not alone. Even many professional mechanics are not yet up to speed on CAN diagnostics. Troubleshooting a late model CAN car is really no different than troubleshooting any late model OBD II vehicles. You need a scan tool to read out fault codes and other sensor data, and you need a scan tool that is CAN compliant. That means it has the proper software and hardware to communicate with the vehicle at higher speeds.

Older scan tools (namely, most of those made before about 2006) lack the circuitry to talk to a CAN system. Some older scan tools have the right hardware, and can be upgraded with new software. But in most cases you will need a newer scan tool that is CAN-compliant to do onboard diagnostics.

Most inexpensive scan tools designed for the DIY market are on-e-way tools: they can read codes and data, but they cannot send commands to the vehicle that are necessary to run all kinds of system self-tests. That degree of sophistication is reserved for more expensive professional level scan tools or factory scan tools. In addition, the software in a typical DIY scan tool (even if it is CAN-compliant) can usually only access powertrain codes. It can't talk to the ABS system, climate control system, electronic steering or suspension systems, climate control system, airbag system or other onboard electronics. In other words, it is a very limited tool. For advanced diagnositics that go beyond sijply reading powertrain fault codes and sensor data, you need a professional level tool or a factory tool. The latter can be quite expensive, costing thousands of dollars -- plus annual software updates that can add hundreds more. So if you need advanced diagnostics, the only option for most motorists and DIYers is to take your vehicle to a repair shop that has the proper diagnostic equipment.

How Information Moves Around in a CAN System

Like many current vehicles, information in a CAN-equipped vehicle is shared over a serial data bus. The bus is the circuit that carries all the electronic chatter between modules (nodes). The bus may have one wire or two. If it has two, the wires are usually twisted to cancel out electromagnetic interference. The speed at which the bus carries information will vary depending on the "class" rating of the bus as well as the protocol to which it conforms.

A data bus with a "Class A" speed rating is a relatively slow, low-speed circuit that typically carries less than 10 kilobits (10 Kbps) of information per second. A data bus that operates at Class A speeds is limited to simple command functions like operating power mirrors, power seats, power widows, power door locks, remote trunk releases and lights.

A data bus with a "Class B" rating, by comparison, may operate from 10 Kbps up to 125 Kbps, depending on the operating protocol (SAE J1850 or Europe's ISO 9141-2). This is fast enough to carry more complex information and time-sensitive data. Systems that may may share a data bus with a Class B rating include electronic instrumentation, electronic transmission controls, security systems, and climate control.

Class C is currently the fastest data bus rating. Class C systems can operate at speeds up to 1 megabits per second, which is up to 100 times faster than a typical Class B data bus. Many of the vehicles that are currently using a Class C data bus are operating at speeds of around 500 Kbps, which is fast enough for powertrain control modules, air bag modules, and fast-acting antilock brake and stability control systems. Eeven faster CAN systems are coming with "class D" ratings of over 1 megabytes per second. And some applications such as onboard entertainment systems require even higher speed audio and video streaming.

One thing to keep in mind about the CAN standard is that CAN as well as other protocols such as SAE J1939, GMLAN, OBD II, SAE J1587 and LIN have more to do with the way information is formatted, transmitted and received than how fast it is sent. This means the automotive engineers who design the onboard electronics for CAN-compliant vehicles are free to choose any operating speed they want (up to one megabits per second) as well as the type of bus conductor (one wire, twisted paired wires or a fiber optic cable). On most cars today, a high-speed data bus is needed to handle the volume of information going back and forth between all the onboard electronics.

In 1995, GM introduced its own "Class 2" data bus to handle communication between modules. The system ran at a speed of 10,400 bits per second (10.4 Kbps), which was more than adequate for vehicles a decade ago. In 2004, GM moved to their next generation data bus system which they called "GMLAN" (GM Local Area Network). Introduced on the Cadillac XLR and Saturn Ion, GMLAN added the capability to operate at two speeds on two separate buses: a low speed (33.33 Kbps) bus and a high speed (500 Kbps) bus.

The low speed side of the GMLAN system operates on a single wire bus to handle body-related control functions, while the high speed bus uses two wires to carry data between the powertrain, transmission and antilock brake modules. A "gateway" node connects the high speed bus and low speed bus, and allows information to be shared back and forth. For example, the radio (which is connected to the low speed bus) may adjust volume based on engine speed and vehicle speed (from the high speed bus) to offset road noise.

Mercedes also uses several different bus speeds on their vehicles. Depending on the application, there may be a high-speed 500 Kbps CAN-C bus for the powertrain, transmission and ABS modules, and a slower-speed 83 Kbps CAN-B bus for the body control functions. On some Mercedes cars, there may be as many as 30 modules on the CAN-B bus. Up to model year 2002, all communication between the CAN-C and CAN-B bus went through the electronic ignition switch (EIS) module. After 2002, a new "gateway" module handles the inter-bus communications as well as onboard diagnostics via a CAN-D bus.

.

How CAN Data is Sent and ReceivedIf your eyes haven't glazed over yet, here's how data is sent and received in a CAN system. Every module (node) that is attached to the data bus network is capable of sending and receiving signals. Each module (node) has its own unique address on the network. This allows the module to receive the inputs and data it needs to function, while ignoring information intended for other modules that share the network. When a module transmits information over the network, the information is coded so all the other modules recognize where it came from.

Data is sent as a series of digital bits consisting of "0's" and "1's". If you looked at the data on a scope, you would see a square wave pattern that changes between a high and low voltage reading. The low voltage reading usually corresponds to the "0" while the high voltage reading corresponds to the "1". The actual voltage readings will vary depending on the application and protocols the vehicle manufacturer is using, but most operate in the 5 to 7 volts range.

The CAN standard requires a "base frame" format for the data. What this means is that for each distinct message sent or received by a module on the network, there is a beginning bit (called the "start of frame" or "start of message" bit), followed by an "identifier" code (an 11 bit code that tells what kind of data the message contains), followed by a priority code ("remote transmission request") that says how important the data is, followed by 0 to 8 bytes (one byte equals 8 bits) of actual data, followed by some more bits that verify the information (cyclic redundancy check), followed by some end of message bits and an "end-of-frame" bit.

Still with me? There's more! One of the tasks of any network system is to keep all the messages separated so they don't collide and garble one another. Usually the body control module or instrument cluster module is assigned the task of managing the network traffic. When it sees a message coming over the bus, it looks at the first bit in the data stream. If the bit is a "0", the message is given priority over the others. This is called a "dominant" message. If the first bit is a "1" it is given a lower priority (a "recessive" message). Thus, the highest priority messages always get through to their intended destinations but the low priority messages may be temporarily blocked until the traffic eases up.

CAN Faults

CAN FaultsCAN-compliant vehicles are just as vulnerable to electronic faults as older vehicles. Though CAN systems use fewer wires and fewer connectors to save weight and cost, they also use more modules and more complicated modules. Communication problems can occur if module connectors become corroded or loose, if wires become grounded, shorted or break, or system voltage is below specifications. Some modules may even forget their settings or locations if the battery is disconnected or goes dead.

On some Chrysler minivans, for example, the automatic climate control system will quit working if battery power is lost. This happens because the electric stepper motors that control the position of the blend doors forget their locations. The system has to be put into a "relearn" mode to re-establish all the motor locations and settings.

Various kinds of problems can occur on other CAN-equipped vehicles when the battery is disconnected or goes dead. The modules in the CAN system require a certain amount of voltage for their Keep Alive Memory settings. If this is lost, the module will forget these settings and may not function properly until it has time to relearn the lost data. In some cases, this requires a special relearn procedure using a scan tool because the module can't do the relearn by itself. And on some vehicles, the module may go to sleep and not wake up until it is pinged by a scan tool or the main gateway module (usually the body control module). Relearning procedures typically require a factory scan tool or a professional level aftermarket scan tool.

One of the features of CAN and other network systems is that modules can send and receive "ok" signals to let the main control module know if they are working or not. In theory, this makes diagnostics easier. On the other hand, it also means that one misbehaving module may generate enough noise to disrupt the entire network causing a complete shutdown of the vehicle!

When a serial bus communication problem occurs, it will usually set a "U" diagnostic trouble code (DTC) and turn on the Malfunction Indicator Lamp (MIL). Depending on the fault, the vehicle may or may not start, or it may only operate in a "limp-in" mode with limited capabilities. Loss of communication between the engine controller and transmission controller (code U1026 on a GM, for example) may put the transmission into a limp-in mode where it will only operate in one or two gears.

Loss of communication codes may indicate a wiring problem on the bus, or a fault with a module. Isolating the fault may require unplugging modules one at a time until the fault is found. Just remember that all modules on a bus network need three things to function properly: power, ground and a serial data connection.

When diagnosing bus or module communication problems, you usually start by checking for voltage at the module, then the ground connection, and finally the data line. If all three are good but the module isn't working, the module needs to be replaced.

On GM applications, a code U100 or U1255 means a general loss of communication on the data bus. With a Tech 2 scan tool, you can go to Diagnostic Circuit Check, then Message Monitor to see a list of active modules and compare it to the list of modules that are supposed to be on when the key is on.

To minimize the parasitic current drain on the battery when the vehicle is off, a "sleep" signal is sent to the modules on the network. Some may remain on for a short period of time after the ignition is switched off (air bag module, for example), and some may never go to sleep (anti-theft module and keyless entry receiver, for example) but most are put into a sleep mode to save battery power. If the sleep signal is never sent, or a module fails to recognize the sleep signal, it may remain active and pull power from the battery. Depending on the current draw, this may run down the battery if the vehicle sits for a period of time.

.

.